مسكن

>

working principal of cement plant

مسكن

>

working principal of cement plant

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

working principal of cement plant

Digitization and the future of the cement plant McKinsey

2020年9月16日 The cement plant of the future achieves considerably lower operating costs and higher asset value through higher energy efficiency, yield, and throughput. More targeted and effective maintenance lengthens the lifetime of equipment. Each plant’s

Cement Plant an overview ScienceDirect Topics

96 行 1 Introduction. Cement plants, steel mills and refineries are responsible for a significant share of carbon dioxide (CO2) emissions ( EEA, 2020 ), which are among the

进一步探索(PDF) Cement plant operation handbook Academia.eduCement Plant Operation Handbook [PDF Document]

Cement Production an overview ScienceDirect Topics

1 Introduction Cement production is a thermal energy intensive process, which requires heating solid particles up to 1450°C and cooling it down. The process generates hot and

进一步探索Cement Manufacturing Process Simplified Flow Chart(PDF) Cement Manufacturing ResearchGate

Cement Quarrying, Blasting, Beneficiation, and Grinding

There are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the

Cement manufacturing components of a

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the

working principle of a cement plant :: HAOMEI

2020年8月27日 working principle of a cement plant. Concrete batching plant is divided into four parts: sand feeding, powder (cement, fly ash and expansive agent etc.), water and

Working principle of cement silo TONG JIN JIN

Its working principle is as follows: 1. When install the bulk cement silo, it must be lifted by a special crane. And then place it on the pre-precast concrete foundation. Check the

Instrumentation for cement plants Systems

Complete turn-key analysis system for continuous emission monitoring, process gas measurements and specific applications in the cement industry. ABB provides complete turn-key analysis systems. Continuous gas

Cement Plant Cyclone Preheater

Cyclone Preheater Working Principle The cyclone preheater adopts the multi-stage circulation suspension preheating mode, which makes the raw meal powder and the high-temperature hot air flow accumulated in the

working principal of cement plant pastorale

The working principle of cement silo is as follows: 1.Surge bin after fixed by cement bulk cement trucks transport to the site, and then the transfer line of bulk cement vehicle and

Digitization and the future of the cement plant McKinsey

2020年9月16日 There’s never been a more important time to build resilience into the core of the cement value chain: the cement plant. The cement industry is being hit hard by the COVID-19 pandemic, with global demand for cement expected to decline by 7 to 8 percent in 2020—though these declines have been unevenly distributed across regions. 1 Paul

The Cement Manufacturing Process Thermo Fisher

2015年8月20日 Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln. In this process, the chemical bonds of the raw materials are broken down and then they are

[PDF]

[J. Res. Natl. Inst. Stand. Technol. Concrete Mixing

2001年5月23日 Introduction As for all materials, the performance of concrete is determined by its microstructure. Its microstructure is determined by its composition, its curing conditions, and also by the mixing method and mixer conditions used

Concrete Batch Plant Work Components

2017年5月25日 Atlas Industries Concrete plants Before we understand the working or operation of a concrete batch plant .It is important to understand the basic components and structure of a batching plant. We have mobile

(PDF) Evaluation of Asphalt Plants in Terms of

2010年8月6日 Working principle of baghouse is the same as a . vacuum cleaner. (QC) operation is performed for products of the asphalt concrete batching plant (ACBP) is one of the key factors that will

Working principle of cement silo TONG JIN JIN

Its working principle is as follows: 1. When install the bulk cement silo, it must be lifted by a special crane. And then place it on the pre-precast concrete foundation. Check the verticality between the cement tank and the horizontal plane, then weld the bottom of the cement tank firmly with the embedded parts of the foundation.

Working Principle of Cement Silo Jinsheng Construction

2022年11月3日 Cement silo is suitable for storing various bulk materials such as grain, cement and fly ash. The tank is equipped with a material level system to show the position of the material. Cement silo is mainly used to store cement, fly ash and other raw materials for concrete production in concrete batching plant.. Working principle of cement silo

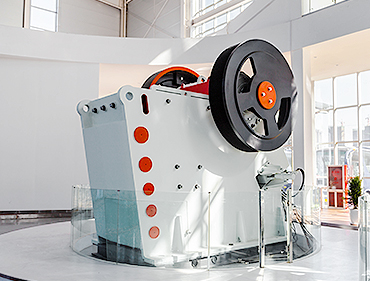

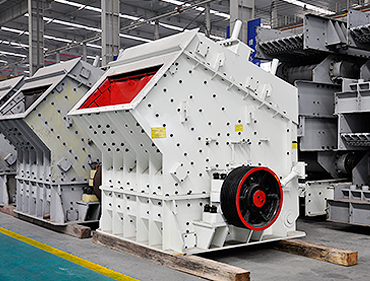

Hammer Crusher Working Principle AGICO Cement Plant

This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone, coal, and other medium hardness ores. It is mainly composed of a transmission device, rotor, lining plate, grate screen, and shell. 1. Shell. The shell is composed of the lower body, the upper rear cover, the left and the right side walls.

Cyclone preheater in cement plant

Working principle of cyclone preheater The cyclone preheater is consist of six parts, including the upper feeding system, preheater, roller pusher, hydraulic system, lower feeding room, and etc.

Working Principle of Cement packing machine

2017年1月6日 Working principles of LG-8 Cement Packing Machine: In spiral cement packing plant, traditional ash conveyance by impeller is changed into spiral ash conveyance by bulking and thereby the problem

Digitization and the future of the cement plant McKinsey

2020年9月16日 The cement plant of the future achieves considerably lower operating costs and higher asset value through higher energy efficiency, yield, and throughput. More targeted and effective maintenance lengthens the lifetime of equipment. Each plant’s environmental footprint is minimized, securing its license to operate across locations and

The Cement Manufacturing Process Thermo Fisher

2015年8月20日 Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln.

[PDF]

[J. Res. Natl. Inst. Stand. Technol. Concrete Mixing

2001年5月23日 Introduction As for all materials, the performance of concrete is determined by its microstructure. Its microstructure is determined by its composition, its curing conditions, and also by the mixing method and mixer conditions used

(PDF) Evaluation of Asphalt Plants in Terms of

2010年8月6日 Working principle of baghouse is the same as a . vacuum cleaner. (QC) operation is performed for products of the asphalt concrete batching plant (ACBP) is one of the key factors that will

(PDF) Assessment on Cement Production Practice and

2020年1月1日 In Ethiopia, the demand for cement has been growing since then and in 2008 there were four cement plants with a combined production capacity of about 2.85 million metric tons per year as reported

Working principle of cement silo TONG JIN JIN

Its working principle is as follows: 1. When install the bulk cement silo, it must be lifted by a special crane. And then place it on the pre-precast concrete foundation. Check the verticality between the cement tank and the horizontal plane, then weld the bottom of the cement tank firmly with the embedded parts of the foundation.

Hammer Crusher Working Principle AGICO Cement Plant

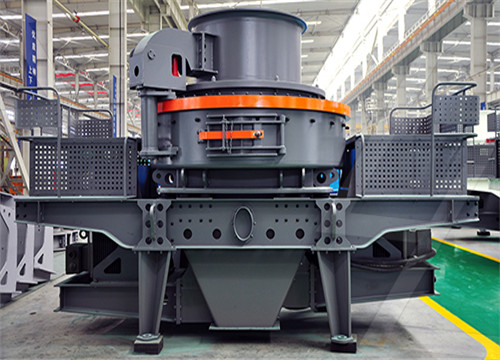

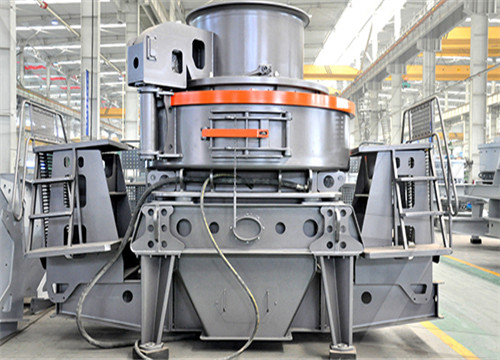

cement plant construction Hammer Crusher Working Principle The hammer crusher is a type of ore crushing equipment. It can be used to crush medium-hard brittle materials with low water content, such as limestone, gypsum, slag, coke, coal, etc. It is widely used in cement manufacturing, chemical, electric power, metallurgy, and other industries.

Cyclone preheater in cement plant

Working principle of cyclone preheater The cyclone preheater is consist of six parts, including the upper feeding system, preheater, roller pusher, hydraulic system, lower feeding room, and etc.

Working Principle of Cement packing machine

2017年1月6日 Working principles of LG-8 Cement Packing Machine: In spiral cement packing plant, traditional ash conveyance by impeller is changed into spiral ash conveyance by bulking and thereby the problem

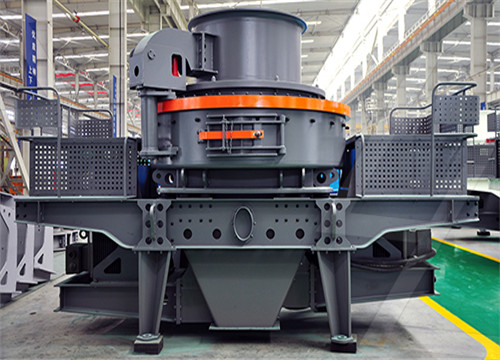

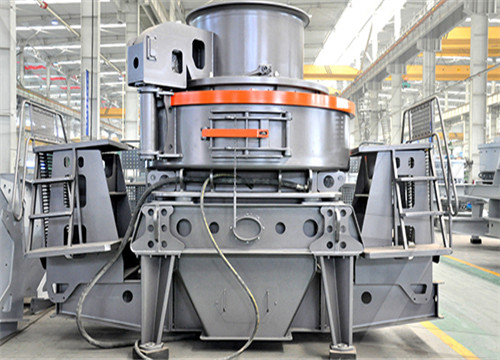

Cement Milll Separator Cyclone Air Separator in Cement

The working principle is designed according to aerodynamics analysis, which reduces the air resistance during production and increases efficiency; The main shaft of the separator is designed to work at high speed. It is convenient to adjust the

Cement Production an overview ScienceDirect Topics

1 Introduction Cement production is a thermal energy intensive process, which requires heating solid particles up to 1450°C and cooling it down. The process generates hot and

Cement Quarrying, Blasting, Beneficiation, and Grinding

There are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the

Cement manufacturing components of a

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the

working principle of a cement plant :: HAOMEI

2020年8月27日 working principle of a cement plant. Concrete batching plant is divided into four parts: sand feeding, powder (cement, fly ash and expansive agent etc.), water and

Working principle of cement silo TONG JIN JIN

Its working principle is as follows: 1. When install the bulk cement silo, it must be lifted by a special crane. And then place it on the pre-precast concrete foundation. Check the

Instrumentation for cement plants Systems

Complete turn-key analysis system for continuous emission monitoring, process gas measurements and specific applications in the cement industry. ABB provides complete turn-key analysis systems. Continuous gas

Cement Plant Cyclone Preheater

Cyclone Preheater Working Principle The cyclone preheater adopts the multi-stage circulation suspension preheating mode, which makes the raw meal powder and the high-temperature hot air flow accumulated in the

working principal of cement plant pastorale

The working principle of cement silo is as follows: 1.Surge bin after fixed by cement bulk cement trucks transport to the site, and then the transfer line of bulk cement vehicle and

Digitization and the future of the cement plant McKinsey

2020年9月16日 There’s never been a more important time to build resilience into the core of the cement value chain: the cement plant. The cement industry is being hit hard by the COVID-19 pandemic, with global demand for cement expected to decline by 7 to 8 percent in 2020—though these declines have been unevenly distributed across regions. 1 Paul

The Cement Manufacturing Process Thermo Fisher

2015年8月20日 Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln. In this process, the chemical bonds of the raw materials are broken down and then they are

[J. Res. Natl. Inst. Stand. Technol. Concrete Mixing

2001年5月23日 Introduction As for all materials, the performance of concrete is determined by its microstructure. Its microstructure is determined by its composition, its curing conditions, and also by the mixing method and mixer conditions used

Concrete Batch Plant Work Components

2017年5月25日 Atlas Industries Concrete plants Before we understand the working or operation of a concrete batch plant .It is important to understand the basic components and structure of a batching plant. We have mobile

(PDF) Evaluation of Asphalt Plants in Terms of

2010年8月6日 Working principle of baghouse is the same as a . vacuum cleaner. (QC) operation is performed for products of the asphalt concrete batching plant (ACBP) is one of the key factors that will

Working principle of cement silo TONG JIN JIN

Its working principle is as follows: 1. When install the bulk cement silo, it must be lifted by a special crane. And then place it on the pre-precast concrete foundation. Check the verticality between the cement tank and the horizontal plane, then weld the bottom of the cement tank firmly with the embedded parts of the foundation.

Working Principle of Cement Silo Jinsheng Construction

2022年11月3日 Cement silo is suitable for storing various bulk materials such as grain, cement and fly ash. The tank is equipped with a material level system to show the position of the material. Cement silo is mainly used to store cement, fly ash and other raw materials for concrete production in concrete batching plant.. Working principle of cement silo

Hammer Crusher Working Principle AGICO Cement Plant

This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone, coal, and other medium hardness ores. It is mainly composed of a transmission device, rotor, lining plate, grate screen, and shell. 1. Shell. The shell is composed of the lower body, the upper rear cover, the left and the right side walls.

Cyclone preheater in cement plant

Working principle of cyclone preheater The cyclone preheater is consist of six parts, including the upper feeding system, preheater, roller pusher, hydraulic system, lower feeding room, and etc.

Working Principle of Cement packing machine

2017年1月6日 Working principles of LG-8 Cement Packing Machine: In spiral cement packing plant, traditional ash conveyance by impeller is changed into spiral ash conveyance by bulking and thereby the problem

Digitization and the future of the cement plant McKinsey

2020年9月16日 The cement plant of the future achieves considerably lower operating costs and higher asset value through higher energy efficiency, yield, and throughput. More targeted and effective maintenance lengthens the lifetime of equipment. Each plant’s environmental footprint is minimized, securing its license to operate across locations and

The Cement Manufacturing Process Thermo Fisher

2015年8月20日 Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln.

[J. Res. Natl. Inst. Stand. Technol. Concrete Mixing

2001年5月23日 Introduction As for all materials, the performance of concrete is determined by its microstructure. Its microstructure is determined by its composition, its curing conditions, and also by the mixing method and mixer conditions used

(PDF) Evaluation of Asphalt Plants in Terms of

2010年8月6日 Working principle of baghouse is the same as a . vacuum cleaner. (QC) operation is performed for products of the asphalt concrete batching plant (ACBP) is one of the key factors that will

(PDF) Assessment on Cement Production Practice and

2020年1月1日 In Ethiopia, the demand for cement has been growing since then and in 2008 there were four cement plants with a combined production capacity of about 2.85 million metric tons per year as reported

Working principle of cement silo TONG JIN JIN

Its working principle is as follows: 1. When install the bulk cement silo, it must be lifted by a special crane. And then place it on the pre-precast concrete foundation. Check the verticality between the cement tank and the horizontal plane, then weld the bottom of the cement tank firmly with the embedded parts of the foundation.

Hammer Crusher Working Principle AGICO Cement Plant

cement plant construction Hammer Crusher Working Principle The hammer crusher is a type of ore crushing equipment. It can be used to crush medium-hard brittle materials with low water content, such as limestone, gypsum, slag, coke, coal, etc. It is widely used in cement manufacturing, chemical, electric power, metallurgy, and other industries.

Cyclone preheater in cement plant

Working principle of cyclone preheater The cyclone preheater is consist of six parts, including the upper feeding system, preheater, roller pusher, hydraulic system, lower feeding room, and etc.

Working Principle of Cement packing machine

2017年1月6日 Working principles of LG-8 Cement Packing Machine: In spiral cement packing plant, traditional ash conveyance by impeller is changed into spiral ash conveyance by bulking and thereby the problem

Cement Milll Separator Cyclone Air Separator in Cement

The working principle is designed according to aerodynamics analysis, which reduces the air resistance during production and increases efficiency; The main shaft of the separator is designed to work at high speed. It is convenient to adjust the